Remote Optical Inspection Device

Product Brief:

The MAPs project was a collaborative R&D project to investigate a novel approach of combining optical hardware and advanced image processing techniques for remote visual inspection of pipework in the nuclear industry.

Our Approach:

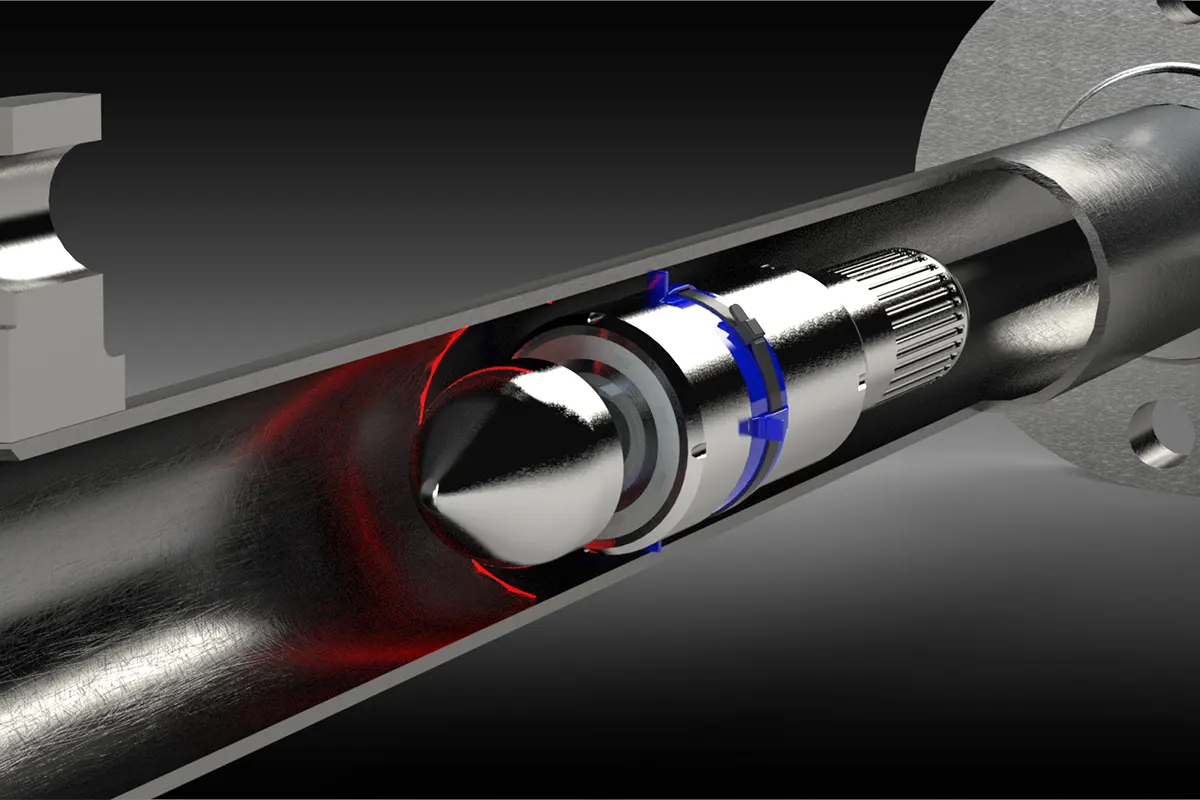

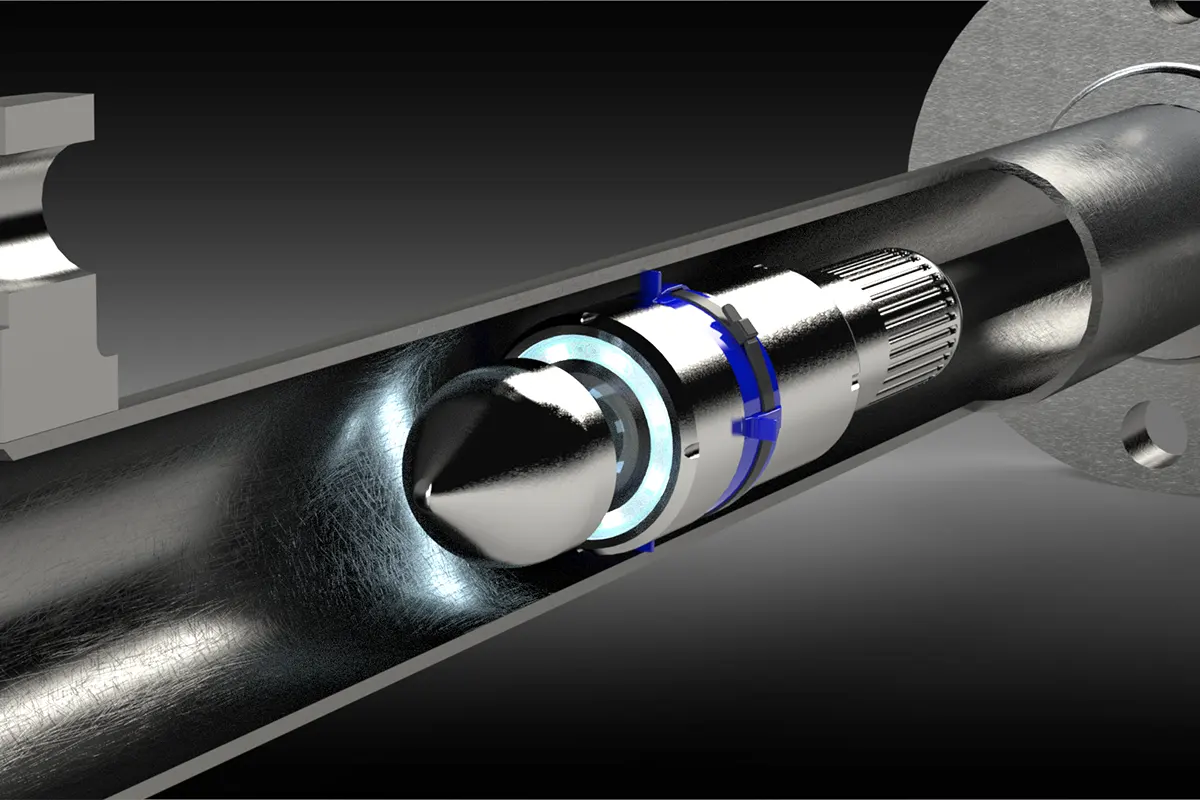

The mechanics of the probe, the electronics and push-rod cable were designed by Wideblue, with the University of Strathclyde developing the image processing techniques. The concept was to use photogrammetry using a fisheye camera and an alternating lighting system to map the internal surface of the pipe.

Wideblue was responsible for:

- The probe was machined from 316 Stainless Steel, with a sapphire optical window.

- A custom cable was developed to facilitate the data and deployment of the probe.

- Electronics used a readily available machine vision camera mated to a small 180° fisheye lens.

- Firmware was developed to trigger the lighting system and capture images at the appropriate time.

- Optical design and testing of the system was carried out at Wideblue.

- 5x Prototypes were developed for each and trialled successfully in the field.

Our Solution:

The result was a small, compact, yet robust probe capable of inspecting pipes and accurately and repeatedly locating and characterising defects inside the structure. The more accurate these inspections are, the more accurate comparisons can be made with previous inspections.