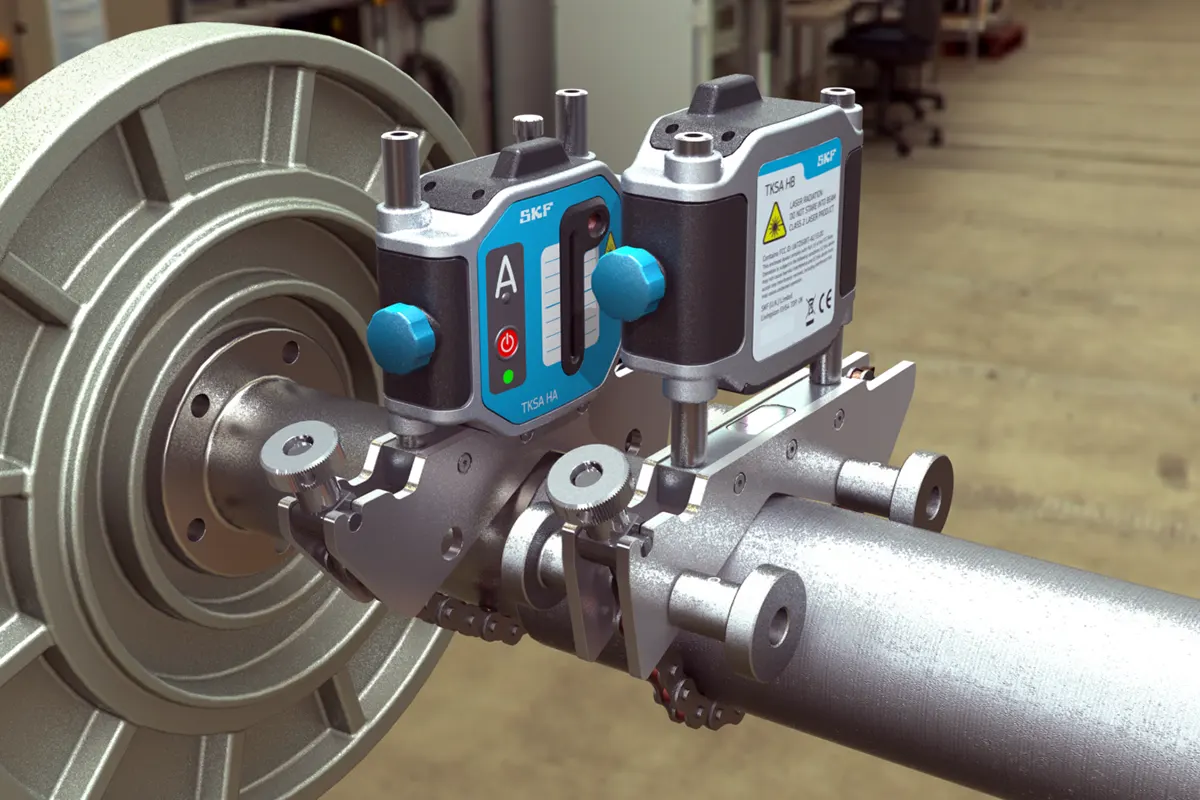

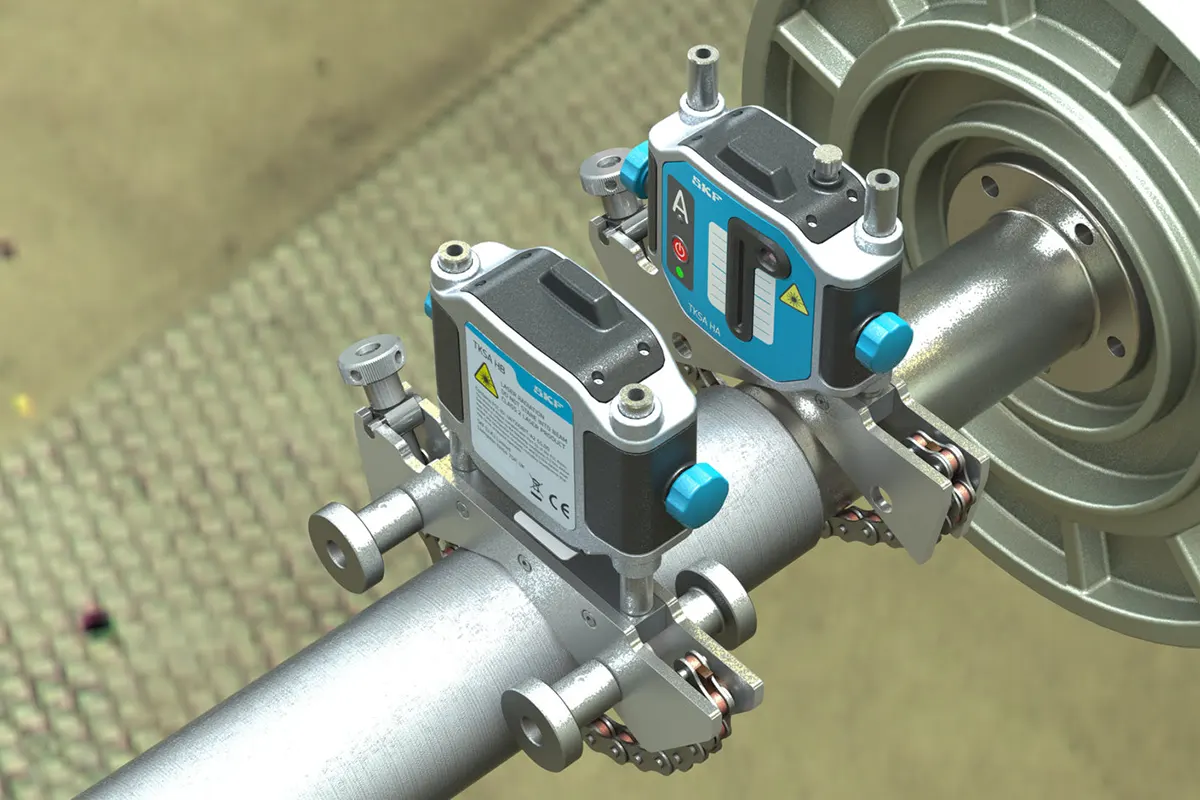

Shaft Alignment System

Project Brief:

SKF’s Centre of Excellence for handheld instrumentation asked Wideblue to collaborate on designing a rugged, shaft-mounted, fully integrated wireless laser alignment system for the high-precision alignment of machine components. The system had to combine precision instrumentation design with a high level of reliability in line with the client’s existing product portfolio.

Our Approach:

Working with the in-house SKF engineering design team, Wideblue used their photonics and system integration skills to design and develop the laser imaging measurement heads and shaft clamping system, integrating both these elements with the SKF-designed handheld controller and application software.

Undertaking this project, we faced critical challenges in designing and integrating the hardware and firmware for a high accuracy imaging system into a small, rugged shaft-mounted enclosure. This industrial design had to be executed in line with SKF corporate requirements.

Our Solution:

The resulting product is a combination of precision optics and imaging components engineered to perform to high levels of accuracy in a challenging application.